Oil Refining Equipment

Oil Refining Equipment:

The "crude oil" produced by an oil press is only a semi-finished product. Refining equipment is used to remove impurities from the crude oil, including gums, free fatty acids, pigments, odor substances, waxes, etc., improving the oil's stability, safety, and sensory quality to obtain edible finished oil.

Main Process Flow and Corresponding Equipment:

Degumming: Removing phospholipids and gums through hydration or acid refining.

Deacidification: Neutralizing free fatty acids in the crude oil with alkali solution.

Decolorization: Removing pigments using adsorbents (such as bleaching clay).

Deodorization: Removing odors and volatiles by introducing steam under high vacuum and high temperature.

Dewaxing (for certain oils such as sunflower oil and corn oil): Removing waxes through freezing, crystallization, and filtration.

Main Applications: This is an essential step in all modern vegetable oil mills. Depending on the grade requirements of the finished oil, a fully continuous, semi-continuous, or batch refining process can be selected.

-

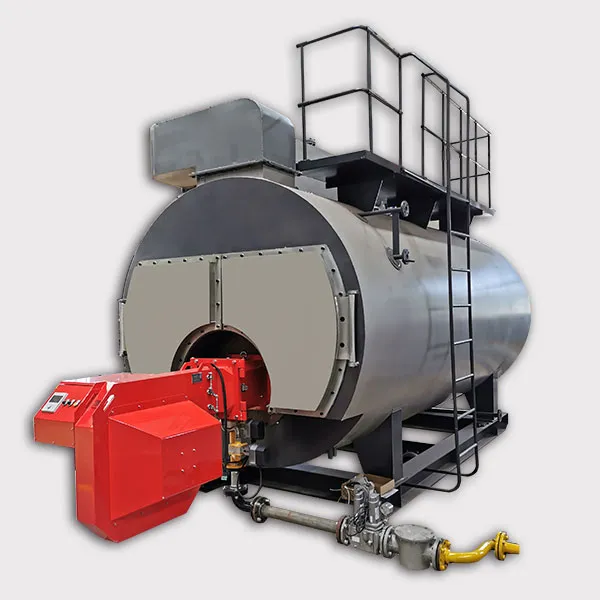

WNS Type Oil And Gas Steam Boiler

WNS series gas (oil) steam boiler for the pot shell type full wet back three-way flue tube structure, the overall use of wet back structure, trigger e...

Add to Inquiry -

CWNS Type Oil And Gas Hot Water Boiler

The cwns-type hot water boiler adopts the flue gas three-way design, which increases the convection area and enhances the effect of convection, and th...

Add to Inquiry

86 156 3978 1876

86 156 3978 1876  86 156 3978 1876

86 156 3978 1876