Nut Oil Production Line

Full-auto nut oil line for walnut, almond, macadamia nut,etc.Integrated process, smart control, retains nutrition, ensures yield & quality for scale production, one-stop from raw nuts to finished oil.

Product Name:Automatic Nut Oil Production Line

Capacity:12-600 kg/h (can be customized according to your needs)

Raw Material: Almond, Walnut, Hazelnut, Macadamia Nut, Cashew Nut, Brazil Nut,

Pine Nut, Pistachio, Peanut, Shea, etc.

Material: 304 Stainless Steel/Carbon Steel

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Question 1-Product Description

Specializing in premium oil extraction from high-value nuts such as walnuts, almonds, macadamia, and hazelnuts.

Providing end-to-end equipment for nut processing, from shelling, low-temperature roasting, pressing/extraction, filtration and refining to bottling. Customized processes preserve nutrients and flavor, meeting the needs of virgin, refined, and specialty nut oil production.

REKATED EQUIPMENT:

Peeling machine, roaster machine, conveyor machine, oil press, oil filter, oil refining machine, filling machine.

CORE STAGES OF A PRODUCTION LINE:

✅ Preparation (Cleaning & Shelling): Removes dirt, stones, and shells from nuts to get pure kernels, improving oil yield and machine life.

✅ Pre-treatment(Roasting/Cooking): Kernels are heated (often to 6-8 maturity for peanuts) to break oil cells, enhancing oil release and flavor, especially for fragrant oils.

✅ Oil Extraction: Nuts are crushed and pressed (screw press) to physically squeeze out oil, common for high-flavor, natural oils (cold pressing for premium).

✅ Oil Filter: To filter the crude oil and get the clean oil.

✅ Refining (Optional but Common): Further processes like degumming, deacidification, decolorization, and deodorization remove impurities, pigments, and odors for refined oil.

✅ Bottling: Automatic filling and sealing.

CONTACT US NOW TO GET YOUR CUSTOMIZED SOLUTION.

Question 2-Product Parameter

NUTS OIL PROCESSING LINE EQUIPMENT

| Product Name | Capacity | Motor Power |

| Peeling Machine | 100kg/h-2000kg/h | 0.75kw-11kw |

| Roaster Machine | 50kg/h-750kg/h | 0.75kw-33kw |

| Conveyor Machine | 500kg/h-3000kg/h | 0.25kw-11kw |

| Hydraulic/Screw Oil Press | 12kg/h-600kg/h | 0.75kw-3kw |

| Oil Fiter | 0.5m³/h-10m³/h | 1.5kw-3kw |

| Oil Refining Machine | 600kg/day-3000kg/day | 20kw-132kw |

| Oil Filling Machine | 1800kg/h | 2.2kw |

Remarks:Can customized capacity according to customers require.

If you want to know the specific quotation of the production line you need, please send us your production requirements.

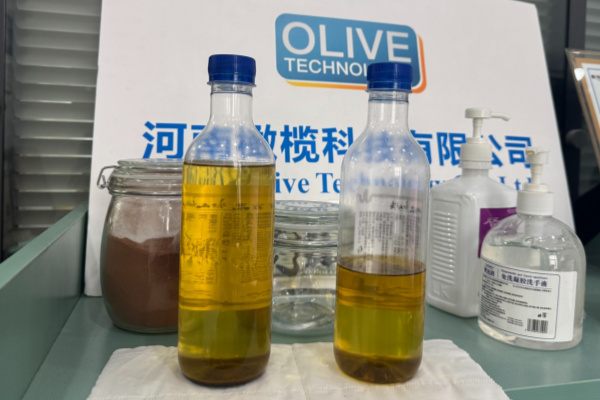

Question 3-Product Display

ADVANTAGES:

| ✅ Integrated Systems: From cleaning/shelling to refining and packaging, the entire process is streamlined. |

| ✅ High Oil Yield: By combining pretreatment equipment with a hydraulic oil press and utilizing low-temperature physical cold-pressing technology, the process not only enhances oil extraction efficiency but also produces specialty oils with distinctive flavors and rich nutrients, such as aromatic oils and cold-pressed oils. |

| ✅ Customization:Capable of processing various nuts and seeds. Adjustable settings allow it to adapt to different types of nuts and production volumes, enabling the creation of a diverse product lineProduction capacity, 200kg-5 tons per day (customizable).. |

Cooking Oil Pressing Line

Cooking Oil Pressing Line

Question 4-Application

CORE APPLICATION SCENARIOS FOR NUTS OIL PRODUCTION LINE:

1. Agricultural Products Processing Base: Whole industry chain empowerment, fresh extraction of original high-quality oil

2. Small-scale Processing Workshop (suitable for small-batch, niche nut oil production): Small-batch customized production, unlock the flavor of niche nut oil

3. Nut Oil For High-end Dietary Field: Natural nutritional premium, renew high-end dietary experience

4. Large-scale Food / Pharmaceutical Enterprises: Professional raw material supply, boost industrial upgrading and quality improvement

5. Customized Configuration: Equipment modules can be flexibly combined based on customer production capacity, raw material types, and product positioning, catering to both small-batch customization and large-scale production.

FOR FURTHER DETAILS OR BESPOKE SOLUTIONS, PLEASE CONTACT US – WE SHALL BE DELIGHTED TO ASSIST!

Question 5-FAQ

Q1: What is the MOQ for your machine?

A: Our MOQ is 1 sets. And any order quantities are highly appreciated.

Q2: Can I get a sample of your machine?

A: Yes, surely, we would like to provide the sample, you just pay for the sample and delivery prime cost.

Q3: What is your guarantee period for your machine?

A: Our machine guarantee period is 12 months, and we also provide 24 hours on-line service if any problems happen.

Q4: Do you accept OEM & ODM?

A: Yes, OEM & ODM projects are available. You are warmly weclome to have your own color, logo, company name, contacts and any design on the machine. Even we are willing to design the color, logo, packages for you.

Q5: Can I test your machine with the raw material when visiting your factory?

A: Yes, surely, any testing our machine with the raw material is highly appreciated.

Q6:What payment do you accept?

A:We accept T/T,Western Union,Paypal,L/C,etc.Normally you need pay 30% deposit in advanced,70% balanced before shipping.

Q7:What's the production time?

A:Usually 5-7 days for MOQ.Other quantity and OEM orders please confirm with us.

Question 6-Our service

OUR ADVANTAGES:

1: Integrated Production and Trade with Quality Control

We own a modern production base and independently research and manufacture core components. Every stage, from raw material selection to processing, undergoes strict quality control.

2: Complete Product Range and Comprehensive Coverage

We offer screw-type, hydraulic, and fully automatic oil presses to meet the needs of different oilseed crops, production capacities, and process flows, and support customized fully automated production lines.

3: Advanced Technology and Customized Solutions

We provide personalized solutions based on your factory space, raw material characteristics, budget, and target output, truly offering a "one-factory, one-solution" approach.

4: Global Service and Full-Cycle Support

We provide comprehensive technical guidance, including factory planning, equipment installation, commissioning, and operation training.

Hot Tags:

none

none

You Might Also Like

-

Low Temperature Cold Pressing Extraction of Sacha Inchi Oil

-

Customized 300L Per Batch Cocoa Butter Deodorization Tank for a Brazilian Customer

-

Philippines Project: 1 Ton Per Day Coconut Oil Refining Equipment Ready for Shipment

-

Australian Customer Case Study - Hydraulic Oil Press for Almond Oil Extraction

-

Core Process Flow of Cocoa Oil Production

-

Polish customer visits factory to inspect goods!

Send Inquiry

No Spam, Just Answers.

By sharing a few key details about your current challenges in the form below, you'll unlock a personalized pathway designed by our experts to not only address your immediate needs but also lay the foundation for sustainable growth and measurable success in the quarters to come.

+86 188 3694 1218

+86 188 3694 1218  +86 188 3694 1218

+86 188 3694 1218